Engineering

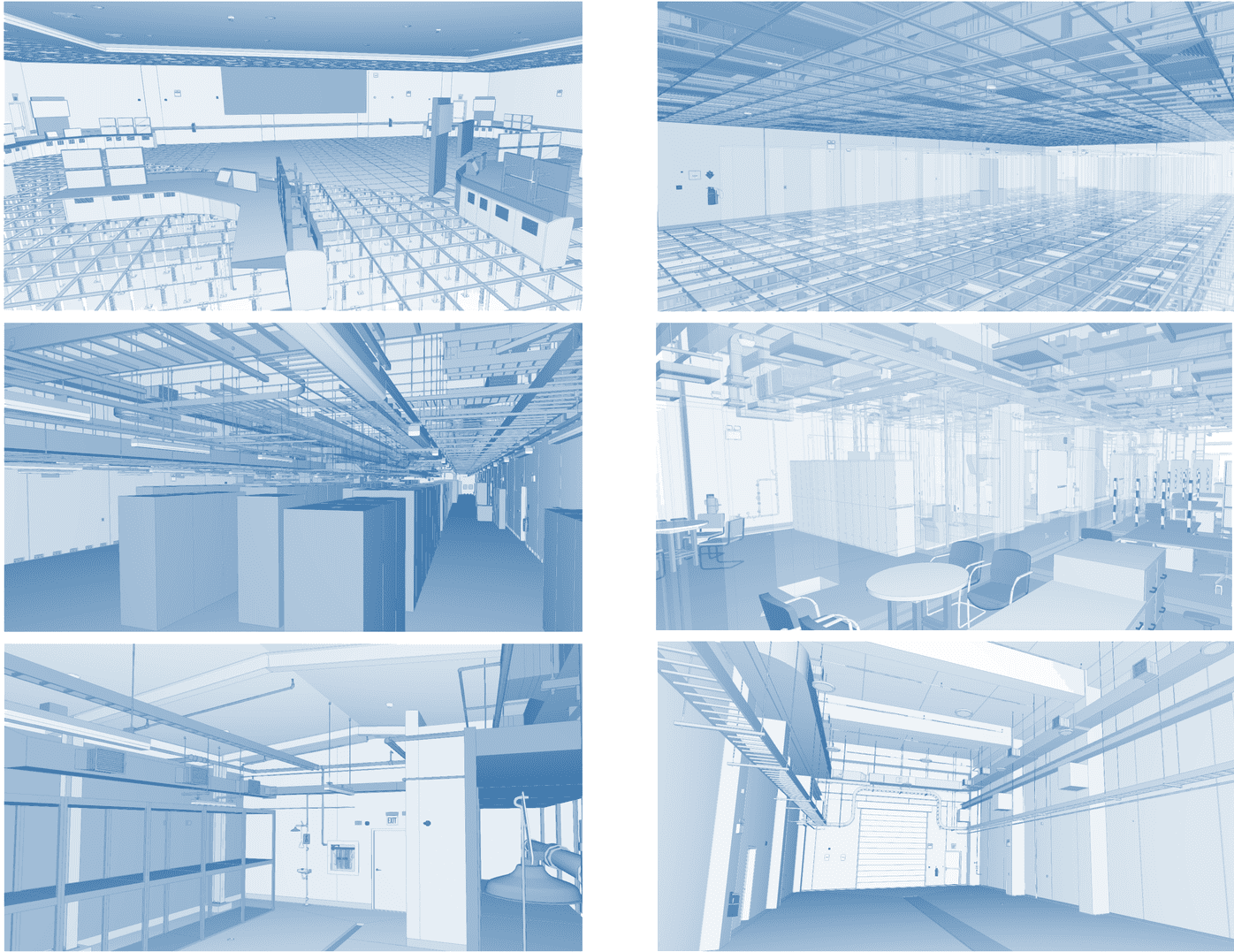

JGC Philippines, Inc. provides a full range of engineering services from feasibility studies to detailed engineering. Using the latest technology in 3D design applications, engineering automation and softwares, we challenge established industry norms to integrate specialized and common technologies to create and deliver clients’ project needs.

Process

JGC Philippines has a wide range of Process Engineering capabilities established through more than 30 years of experience in Engineering, Procurement and Construction (EPC). Process Engineers from JGC Philippines have collaborated with JGC Japan, as well as many local and international clients, in executing EPC projects in a variety of fields such as Oil and Gas, Chemicals, Mining, Oleochemicals, Renewable Energy Solutions and Power Generation in both brownfield and greenfield environments.

We have a highly experienced team that can deliver the full range of Process Engineering services for the entire project life cycle from Feasibility, FEED, EPC up to Commissioning, in addition, JGC Philippines also has access to the full support of JGC Group in terms of expertise and resources as we operate as "One Team" to deliver solutions to our clients.

Our Team is capable of performing all aspects of Process Design such as:

- Project Definition and Development of Design Basis

- Mass and Energy Balances and Process Simulations

- Process Flow and Piping and Instrument Diagrams

- Process Control Design

- Engineering Calculations for hydraulic and Equipment Design

- Advanced Systems Design such as OTS (Operator Training Simulator) and APC (Advance Process Control)

- Design of Plant Safety Systems such as Flare and Relief Systems

- Dynamic Simulation Studies

- HSE Studies such as HAZID, HAZOP and LOPA

- Value Engineering

- Feasibility Studies

- Plant Troubleshooting

- Field Engineering Support

Technical HSE

Our team ensures the design of a safe facility. We establish safety concepts and loss prevention philosophies aligned with client requirements, international standards, and industry practices while ensuring full compliance with regulatory requirements.

We deliver a full range of fire protection and technical safety designs required for complete EPC execution. These include but are not limited to the following:

Fire Protection

Active Fire Protection System Design

- Active Fire Protection Design Basis

- Fire Potential Equipment Identification

- Firewater System Design (Equipment Layout, P&ID, Water Spray System, Foam Systems)

- Equipment Sizing (Fire Pumps, Fire Water Storage Tanks, Foam Tanks) and Process Data Sheets

- Procurement of Fire Fighting and Safety Equipment (Data Sheet, Requisition, Technical Evaluation, Document Reviews)

Passive (Fireproofing) Design

- Fireproofing Design Basis

- Fire Hazardous Equipment Identification (fire potential equipment)

- Fireproofing Zone / Fire Scenario Envelope

- Typical Extent of Fireproofing (structures, equipment steel supports, cables, etc.)

Fire and Gas Detection System Design

- Fire & Gas System Design Basis

- Hazardous Equipment Identification (Flammable Gas, Toxic Gas)

- Fire & Gas System Design (F&G Layout, Block Wiring Diagram, Cause & Effect Diagram)

- Fire & Gas Mapping Study

Design Codes

- Local Regulations and Standards (NFPA, BS, IP/EI, API)

- Client Standards (DEP, MOBIL, BP, CHEVRON, SAES, PTS)

ENGINEERING HSE (Health, Safety and Environment)

Engineering HSE Management

- Engineering HSE Plan

- Safety Critical Element and Performance Standards

- Major Accident Hazard Register

- Design Safety Case

Engineering HSE Philosophies

- Safety and Loss Control Philosophy

- Environmental Design Basis

- Escape, Evacuation and Rescue Philosophy

Engineering HSE Workshop

- HAZID / ENVID

- HAZOP

- SIL / LOPA / IPF Classification

- Human Factor Engineering Assessment

Engineering HSE Risk Analysis Studies

Quantitative Risk Analysis

- Fire and Explosion Risk Analysis

- Smoke and Gas Dispersion Analysis

- Emergency System Survivability Analysis

- Escape, Evacuation and Rescue Analysis

Others

- Hazardous Area Classification

- Escape Route, Muster Point, Safety Sign and Safety Shower Layout

- Dispersion Analysis

- Radiation Contour

- Environmental Impact Assessment

Civil and Structure

With a wide-ranging and proven expertise in Civil and Structural engineering, we provide high value, efficient, and effective solutions to complex plants and industrial facilities.

Our dynamic team has decades of experience and technological know-how to meet diverse plant requirements with excellence.

FRONT-END ENGINEERING DESIGN (FEED)

- Specification for basis of Civil and Structure Design including design codes and material specifications.

- Conceptual Layout for Site Development, Sewer and Drainage, Road and Paving

- Planning and Supervision for Soil Investigation

- Geotechnical Evaluation and Analysis

- Conceptual Layout for Foundation, Piling or Soil Improvement

- Conceptual Layout for Steel and Concrete Structures

- Marine Study and Conceptual Layout

- 2D & 3D preliminary models

- BM/BQ Estimation

ENGINEERING PHASE

- Site investigation, Site development, Piling and Soil improvement

- Sewer, drainage, road and paving design

- Concrete foundation design for Tank, Equipment and Structure,

- Waste water pit, and retention pond design

- Duct bank and Culvert design

- Steel structure design

- Concrete structure design

- Onshore & Offshore Modular structure design including lifting, sea transport, land transport and plant operations

- Evaluation and retrofit design of existing structures.

- Dynamic Analysis for Vibrating Machinery (Compressors, Pumps, Turbine Generator foundation, etc.)

PROCUREMENT PHASE

- Technical Evaluation of Vendors

- Preparation of Requisitions

CONSTRUCTION PHASE

- Field Engineering

- Steel Fabrication Yard Supervision

- Construction Supervision

- Preparation and Review of Shop Fabrication Drawings

- As-built works (drawings, calculation sheets, 3D models)

Photos by: Dale Gallaza and Christopher Reybuenan

- Engineering Tools

- Structure Design software (StaadPro, Staad Offshore, SAP2000, Staad Foundation, SACS, RISAFoundation, SAFE, DynaN, Mat3D)

- Site Development software (OpenRoads, Autoturn Pro ,Civil3D)

- Geotechnical design software (Plaxis 3D and 3D Dynamics, ALLPile, LPile, Novoliq )

- CAD software (AutoCAD, Microstation, Tekla Structures, S3D, Navisworks)

Design Codes and Standards- National Structural Code of the Philippines (NSCP)

- DPWH Manuals and Guidelines

- ACI, AISC, ASCE, AASHTO (American Code)

- JIS (Japanese Code)

- BSI (British Code)

- EN Standards (Eurocode)

- AS4100 (Australian Code)

- SNIP (Russian Code)

- BAEL 91, CM66 (French Code)

Mechanical

A diverse group of experienced engineers wholly in charge of design engineering and handling various mechanical equipment for the Industrial Sector (Oil & Gas, Petroleum and Petrochemical, LNG, Chemical, Thermal Power Plant, Pharmaceutical etc.). The Mechanical department has four (4) core groups/ sections offering technical competencies and experience to cater specific mechanical equipment (Rotating, Static, Combustion, and System Equipment).

FRONT END ENGINEERING DESIGN (FEED)

- Conceptual and preliminary design of mechanical equipment

- Provides FEED documentation

- Assessment, selection and sizing of mechanical equipment

- Conduct material selection

- Equipment cost estimation

ENGINEERING PHASE

- Provides Basic and Detailed Engineering Documents

- General Specifications

- Material Requisitions

- Mechanical Data Sheets

- Detailed Sizing and Rating Calculations

- Engineering Drawings - Mechanical Equipment Selection

- Evaluation of Vendor Bid Proposals

- Technical Evaluation Reports

- Equipment Cost Summary

- Technical Clarification Meeting with Vendors

- Value Engineering and Cost Down Ideas

- Mechanical Handling Engineering

Engineering Tools

- AutoCAD

- Smart Plant 3D

- Navisworks Simulate

- Codeware (Pressure Vesel)

- AspenTech (Heat Exchanger)

- SAP2000

- Staad Pro (Equipment, Platform and Structural)

- NozzlePRO (Local Stress Analysis)

- PRO/II SimSci-Esscor

- HTRI Xchanger

- MecaStack

- FRNC-5PC

- Simu-Therm (Heat Flow Simulation)

- Flaresim

- cStack+

- Liftdes

- J-Crane

Design Codes and Standards

- American Petroleum Institute (API)

- American Society of Mechanical Engineers (ASME)

- American Society for Testing and Materials (ASTM)

- National Fire Protection Association (NFPA)

- International Organization for Standardization (ISO)

- American Institute of Steel Construction (AISC)

- Hydraulic Institute (HI)

- National Association of Corrosion Engineers (NACE)

- International Electrotechnical Commission (IEC)

- Universal Oil Products (UOP)

PROCUREMENT PHASE

- Kick-off Meeting with Vendor

- Vendor Engineering Document Review

- HAZOP/HAZID/SIL Review

- 3D Model Review

- Design Review with Client

- Alarm Management System Review

- Plot Plan and P&ID Review

- MH/BM/BQ Preparation and Review

- Vendor Specialist Planning

- Constructability, Operability & Maintainability Review

- Engineering Coordination with Client, Licensor, Vendors, and Subcontractors

- Inter-Discipline Engineering Coordination

- Vendor Shop Survey

- Pre-Inspection Meeting

- Resident Engineer at Shop

- Factory Acceptance Test

- Integrated FAT

- Vendor Schedule and Order Management

CONSTRUCTION PHASE

- Internal Planning and Coordination

- Vendor Specialist Coordination

- Field Engineering and Supervision

- Coordination with Client, Vendors, and Subcontractors

- Support to Pre-Commissioning, Commissioning, Start-up, Handover, and Warranty Period

Piping

Our Piping Department composed of Piping Design, Mechanical Stress, Materials, 3DIT, and Painting and Insulation is renowned for its extensive experience in delivering cost-effective and innovative piping engineering solutions. We offer comprehensive engineering, procurement, and construction services across a diverse range of sectors including oil & gas, petrochemical, energy transition, healthcare/life sciences, industrial/urban infrastructure, and resource recycling. Our global reach allows us to serve clients overseas, ensuring their projects are executed efficiently and effectively.

FRONT-END ENGINEERING DESIGN (FEED)

- Planning and Control

- Piping Design Specification

- Line List

- Site Survey, Tie In List

- Plot Planning

- Piping Conceptual Layout

- FEED 3D Model

- Specification for Mechanical Stress Analysis

- Piping Material Specification

- Painting and Insulation Specification

- BM/BQ Estimation

ENGINEERING PHASE

- Planning and Control

- Piping Design Specification

- Line List

- Site Survey, Tie In List

- Plot Planning

- Piping Layout

- Heat Tracing Design

- 3D Catalog and Specs Administration

- 3D Model

- Piping Standard Drawings

- Piping Plan and Isometric Drawings

- Specification for Mechanical Stress Analysis

- Piping Stress Analysis

- Piping Material Specification

- Technical Specification, Data Sheets and Requisitions

- Painting and Insulation Specification

- BM/ BQ

Engineering Tools

- Plant Design Application –PDMS (Plant Design Management System), S3D (Smart Plant 3D), E3D (Everything 3D) and AP3D (AutoCAD Plant 3D)

- Stress Analysis – CAESAR II and AutoPIPE

- Design Review –Navisworks

- Material Management – Smart Material by Hexagon with additional functions developed by JGC

- Insulation Thickness Calculation – 3E Plus

Design Codes and Standards

- ANSI, API, ASME, ASTM, AWWA, BS, CINI, IP, ISO, MSS, NACE, NFPA, OSHA, PIP, SSPC

PROCUREMENT PHASE

- Technical Bid Evaluation

- Vendor Document Review

CONSTRUCTION PHASE

- Field Engineering

- Construction Supervision

- Construction Assistance

- Fabrication Drawing Review

- Preparation and Review of Test Packages

- Assist Pre-Commissioning Works

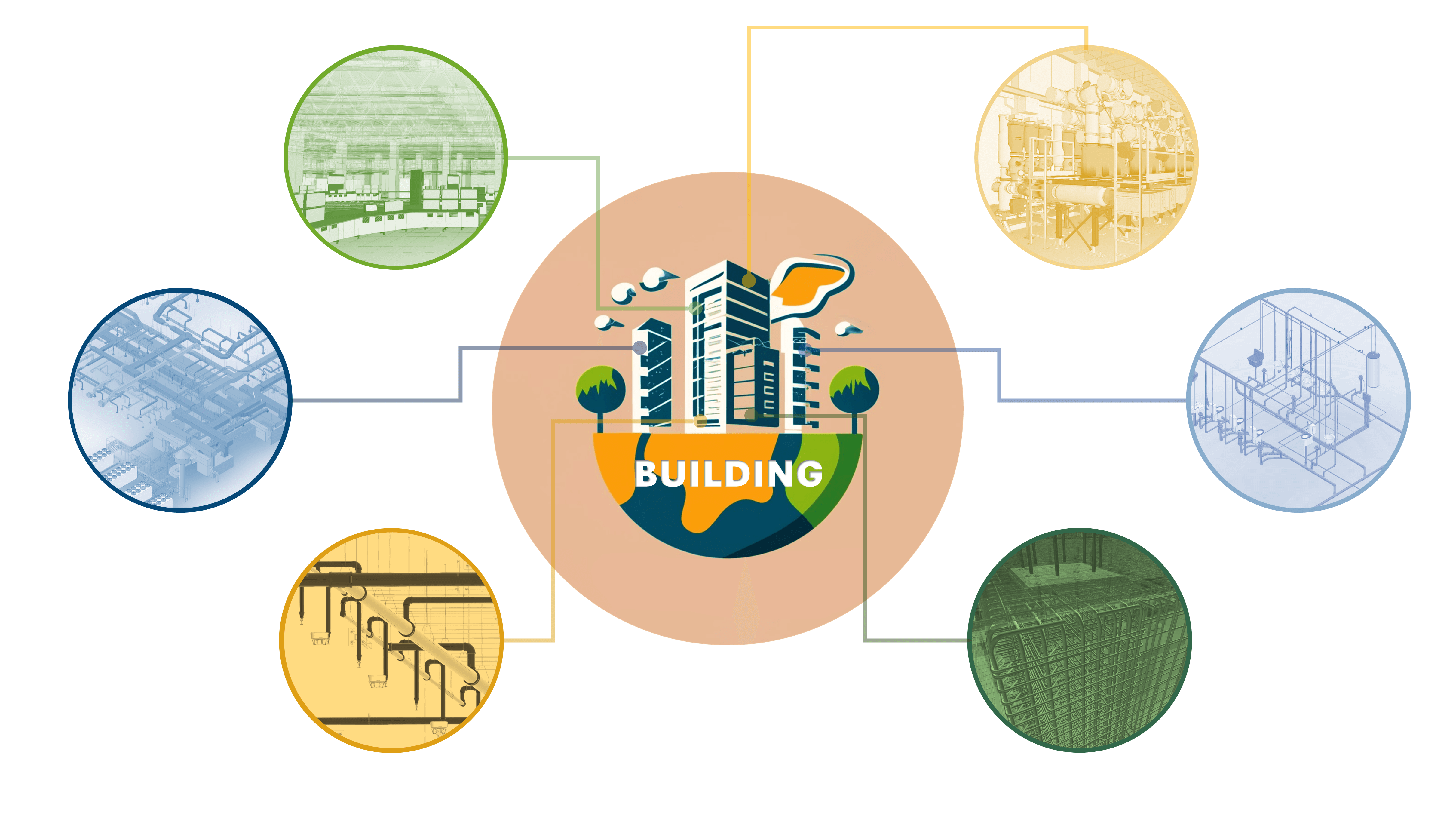

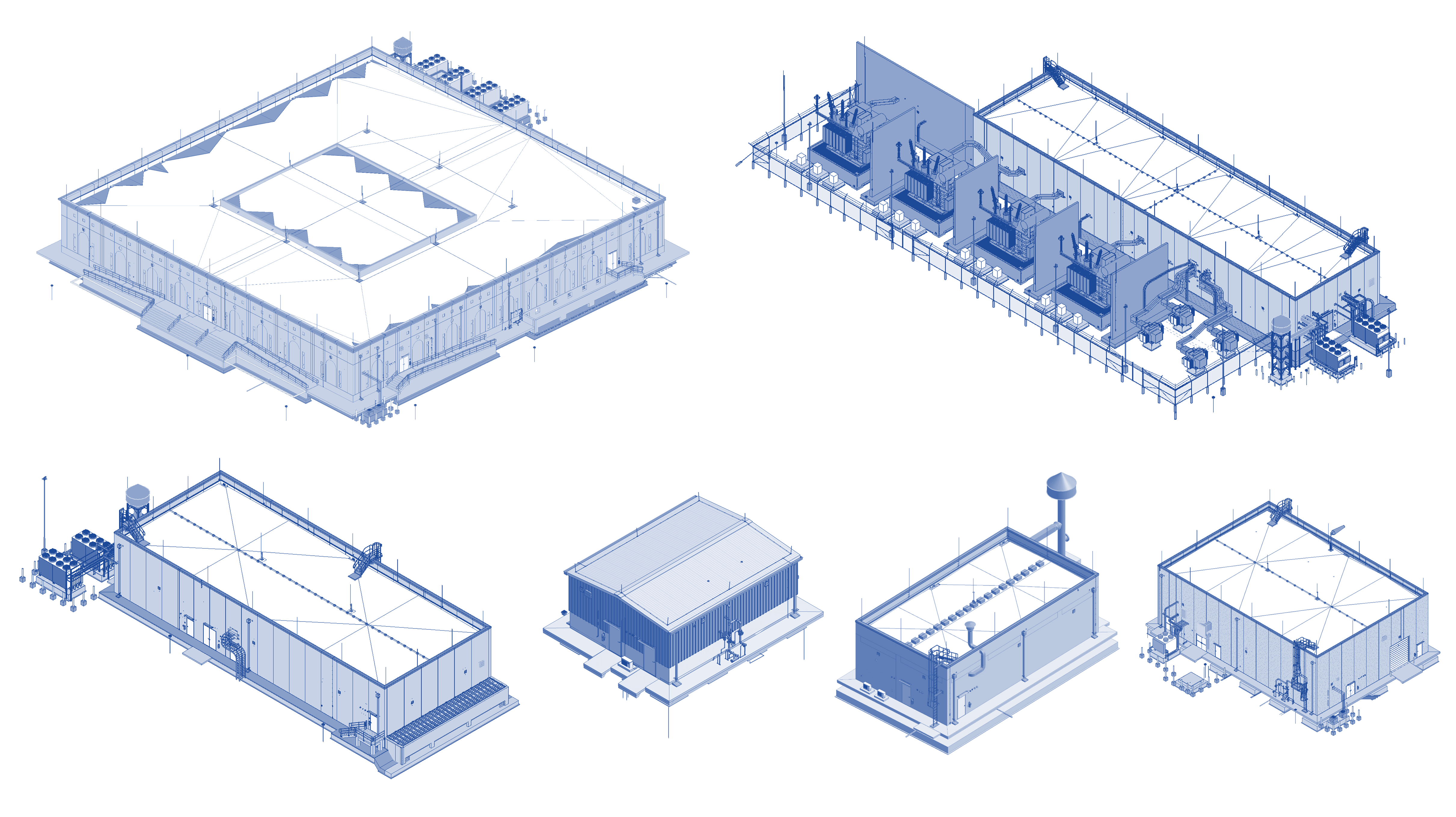

Building

Composed of Multi-Discipline Technical Specialists in the fields of Building Architectural, Structural, HVAC, Plumbing, Electrical and Fire Protection. We specialize in Front End Engineering Design (FEED), Conceptual Design and Detailed Design of Buildings not limited to the following:

- Industrial Buildings (Pre-Cast, Cast-in-Place and Steel)

- Blast Resistant Buildings

- Modular Steel Buildings

- Floating Production and Storage Offloading Buildings

- Pharmaceuticals / Laboratories / Semi-Conductors / Clean Rooms

- Building Retrofitting

- Building Feasibility Study

- Code Compliance Study Report for Existing Buildings

FRONT END ENGINEERING DESIGN (FEED)

- Layouts, Elevations and Sections

- Schematic Diagrams

- 3D Perspectives

- Human Factor and Ergonomic Design Study

ENGINEERING PHASE

- Architectural Detailing

- Interior Design

- Blast Resistant Analysis and Design

- Structural Integrity Analysis

- Seismic Structural Analysis and Design

- Building Retrofit Study and Design

- Sea Fastening and Grillage Design

- Substructure Design and Detailing

- Superstructure Design and Detailing (Reinforced Concrete, Structural Steel, Composite Design, Modular Design)

- Lightning Risk Assessment and Lightning Protection Design

- Lighting and Power System Design

- Grounding System Design

- Auxiliary System Design (CCTV, Access Control and Security, Telephone / LAN, Paging)

- Heating, Ventilation and Air-Conditioning System Design

- Clean Room Design (Pharmaceutical, Chemical, Electronics)

- Plumbing / Sanitary System Design

- Fire Alarm System Design

- Aspirating Detection System Design

- Gas Suppression System Design

- Fire Protection System Design

- Gas Alarm and Detection System Design

- Fire Hazard Analysis Report for Existing Buildings

- Good Manufacturing Practice (GMP) Compliance

- Leadership in Energy and Environmental Design (LEED)

- Building for Ecologically Responsive Design Excellence (BERDE)

- Landscaping

Engineering Tools

- Drafting Software (AutoCAD, MicroStation, etc.)

- Calculation Software (STAAD Pro, MIDAS Gen, Hourly Analysis Program or HAP for HVAC, DIALux Evo, Pipenet, etc.)

- Autodesk Revit and Building Information Modeling (BIM)

Design Codes and Standards

IBC, NBC, NSCP, ASCE, ACI, AISC, UBC, IEC, ASHRAE, UPC, NFPA

PROCUREMENT PHASE

- Technical Evaluation of Vendors

- Preparation of Requisitions

CONSTRUCTION PHASE

- Field Engineering

- Construction Management and Supervision

- Testing and Commissioning of Building Works

- Quality Control Program

- As-Built Works

Electrical

We provide full range of Electrical services from Power Generation to Power Distribution such as Planning, Consultation, Feasibility Study, Front End Engineering Design (FEED), Detailed Engineering, Procurement & Construction of oil refineries, chemical plants, gas plants and other industrial plants.

FRONT END ENGINEERING DESIGN (FEED)

- Establish Electrical Design Philosophy and Key Line Diagram

- Conceptual Layout for Cable Routing

- Conceptual Design for Lighting, Grounding & Lightning Protection

- Establish Telecommunication Design Philosophy and System Block Diagram

- Conceptual Layout of Substation Building

ENGINEERING PHASE

- Electrical Equipment Specifications & Datasheets

- Electrical System Studies (Short Circuit, Load Flow, Relay Coordination, Arc Flash, Harmonics, Motor Starting)

- Grounding Grid Design (Step and Touch Potential Calculation)

- Underground Raceway System Design

- Single Line Diagrams

- Substation Equipment Design

- Power Cabling System

- Lighting Systems

- Grounding & Lightning Protection

- Telecommunication Systems

- Cathodic Protection Systems

- Heat Tracing Systems

Computer-Aided Tools:

- Electrical Transient Analyzer Program (ETAP)

- Smartplant Electrical (SPEL)

- 3D technology – SP3D, E3D, AP3D, Autodesk Revit

- Photovoltaic Software - PVSyst

PROCUREMENT PHASE

- Preparation of Requisitions

- Technical Bid Evaluation

- Vendor Coordination, Inspection & Testing

- Factory Acceptance Test

CONSTRUCTION PHASE

- Field Engineering

- Construction Supervision

- Construction Quality Inspection

- Pre-commissioning and Commissioning

- Hand-over Documentation

Instrument

Our expertise from feasibility studies up to commissioning, technical know-how in the field of instrumentation and control, and strong partnerships provide our clients with what they need.

FRONT END ENGINEERING DESIGN (FEED) PHASE

- Preparation of General Specification for Instrumentation (Field Instrument, Valves, Analyzer & Construction)

- Preparation of Specification for ICSS (DCS, ESD and FGS)

- Preparation of Specification for Modular Instrument

- Instrument Database Development

- Preparation of Overall System Configuration

- Instrument Installation Design (Specification, Typical Drawing)

- Preparation of Conceptual Main Cable Route and Building Equipment Layout

ENGINEERING PHASE

- HAZOP Participation

- LOPA Participation

- SIL Verification

- Others: System Upgrade, and Revamping and Tie-ins

- Instrument Database Development

- Instrument Systems Detailed Design

- Field Instruments, Valves and Instrument Package Design (Specification and Datasheet)

- Instrument Installation Design (Specification, Typical drawing, Layout drawings, 3D modeling)

- Material Take-off

Engineering Tools

- Smartplant Instrumentation (SPI)

- 3D Design - S3D, E3D, AutoCAD 3D

- 3D Design Review - SPR, Navisworks

- Drafting software - AutoCAD, Microstation

Design Codes and Standards

- ANSI, API, ASME, ASTM, IEC, ISO, NACE

PROCUREMENT PHASE

- Preparation of Requisition for Instrument Systems, Field Instruments, Valves, Instrument Packages

- Technical Evaluation of Vendor’s quotations

- Review and approval of Vendor’s drawings and documents

- Testing and Inspection (Factory Acceptance Test (FAT) for DCS/ESD/F&G/Package, Valves, Analyzer Systems, etc)

CONSTRUCTION PHASE

- Field Engineering

- Construction Supervision

- Pre-commissioning Works (DCS/ESD/F&G/Package Site Acceptance Test (SAT), Loop Test, and Function Test)

- Commissioning Support

- Plant Start-up Support

Quality Control

JGC Philippines Incorporated prioritizes Quality Control at every stage of our process, starting from requisition review to material and equipment manufacturing, fabrication, and delivery to the construction site. Our dedicated team of experienced engineers meticulously oversees quality control across diverse disciplines within the EPC framework. Through their expertise, we guarantee the delivery of qualified materials and equipment, adhering to project specifications and internationally recognized codes and standards. Our focus on quality ensures timely delivery to the project’s construction site.

ENGINEERING PHASE

- Requisition review

- Develop quality control plans and inspection procedures.

Engineering Tool - QBIC – QC Database Integrated Control System

PROCUREMENT PHASE

- Specification Review

- Requisition Review

- Vendors Shop Surveys and Technical Capability Review

- Establishment of Vendor’s Inspection and Test Plan (ITP) and Inspection and Test Procedures

- Kick-Off Meeting and Pre-Inspection Meeting with Vendors

- Inspection and Test requirement Execution and Evaluation

- Issuance of Inspection Release Certificate (IRC)

CONSTRUCTION PHASE

- Establishment of Construction Scope Inspection and Test Plan (SITP) and Applicable Inspection and Test Procedures

- Material and Equipment Receiving Inspection

- Civil Works Test and Inspection Verification

- Piping Fabrication and Installation Inspection

- Various Equipment Installation Inspection

Other Services

JGC Philippines procures a wide range of equipment, materials, and services from reliable vendors in accordance with the safety and quality standards, within the schedule, and at a competitive cost. Our Purchasers select the best vendors from..

JGC Philippines was granted the first ”AAAA” PCAB License on August 9, 2016 for General Building and General Engineering. Proven construction solutions at the shortest schedule while adhering to safety and loss prevention. Services include..

Facility Maintenance service is backed by proven engineering technology and extensive experience. Services include maintenance program planning, CMMS implementation, turnaround and shutdown, warehouse management, spare parts..